Depalletiser

- All stainless steel

- Up to 18000 cans per hour

- Available in full-height & reduced height versions

- Siemens touchscreen controls

The depalletiser is a fully automated machine for transferring standard, sleek or slim beverage cans from supplier pallets to the canning line. It is fully integrated with the canning line and uses a Siemens S7-1200 PLC for the control system and a Siemens touchscreen HMI. For optimum hygiene, the depalletiser is manufactured from food grade 304 stainless steel. This ensures robustness and a high level of cleanliness, as well as the safe use of cleaning agents. A food grade grease is specified for machine lubrication. The safety interlock system ensures the operator cannot come into contact with any moving parts of the depalletiser.

The depalletiser features a belt drive linear actuator for smooth and accurate pushing of the cans and photocell sensors to monitor can build-up. A high torque 3.2 kW motor raises and lowers the pallet with precision movement using a heavy duty chain. The HMI touch screen allows the operator to easily manage the automatic setting of pallet layer increments and the automated removal of pallet layer pads is also provided.

Often paired with a lowerator (link) for transporting cans to the canning machine, an ionising air rinser can also be integrated for sterilising cans prior to filling. A high-level conveyor extension with a walkway gantry is also available, which allows monitoring of the conveyor, along with full layer depalletising for increased flow of cans.

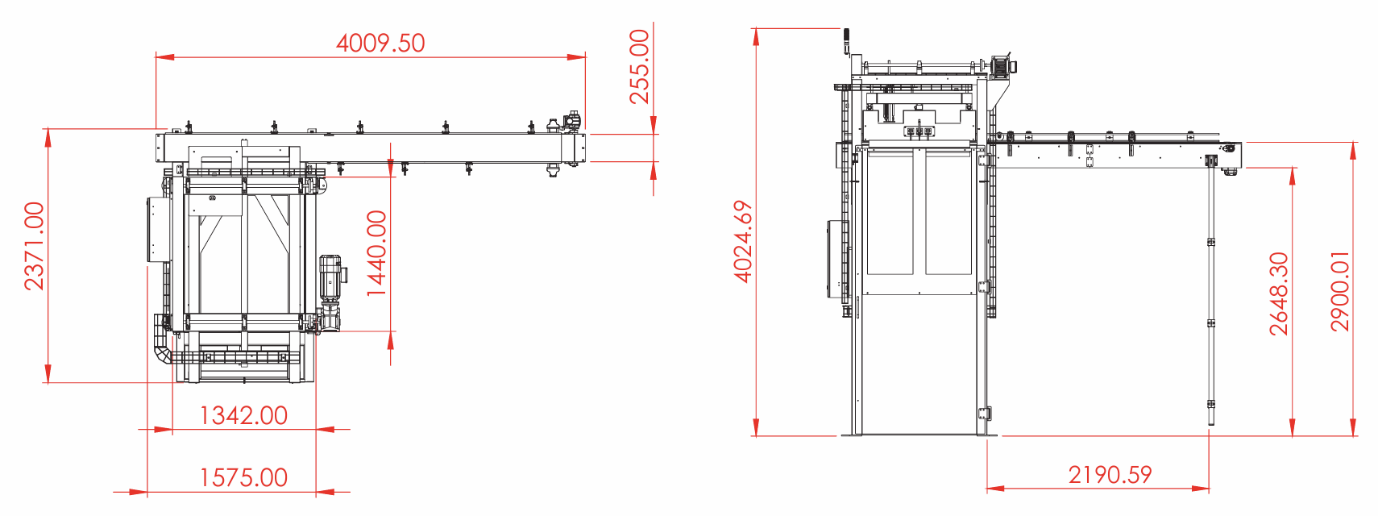

Technical Data

Compressed air input: 10 mm hose push in connector / 3/8" BSP / 10 bar max./ 6 bar min / Maximal consumption of 150L min

Power supply : 3-phase 400V / 50-60Hz, current consumption 16A max (CF15 is 1-phase 240V)

Dimensions: 1575* x 2371 x 4025 mm (W x D x H) *excluding conveyoring